Don't you want to read? Try listening to the article in audio mode 🎧

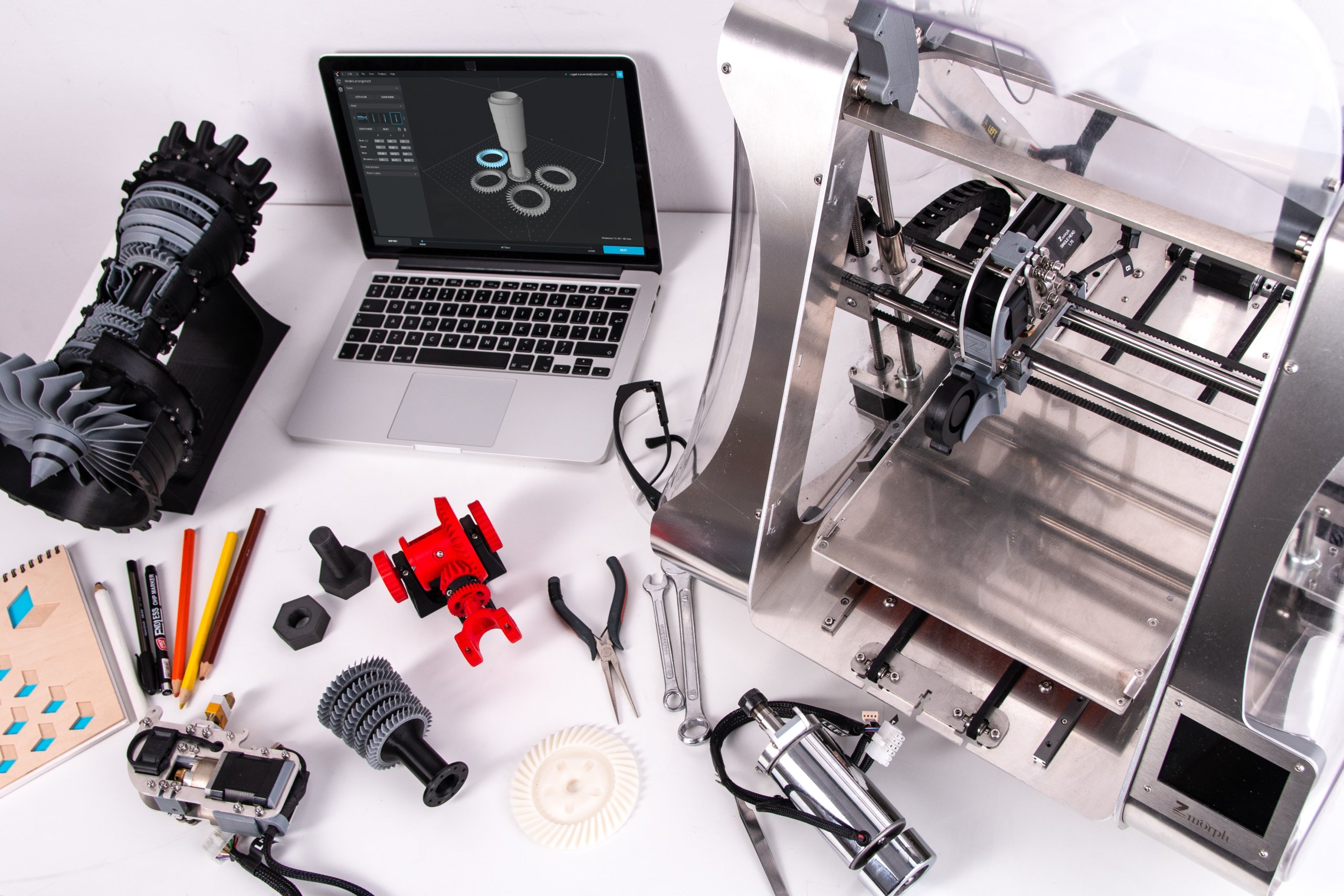

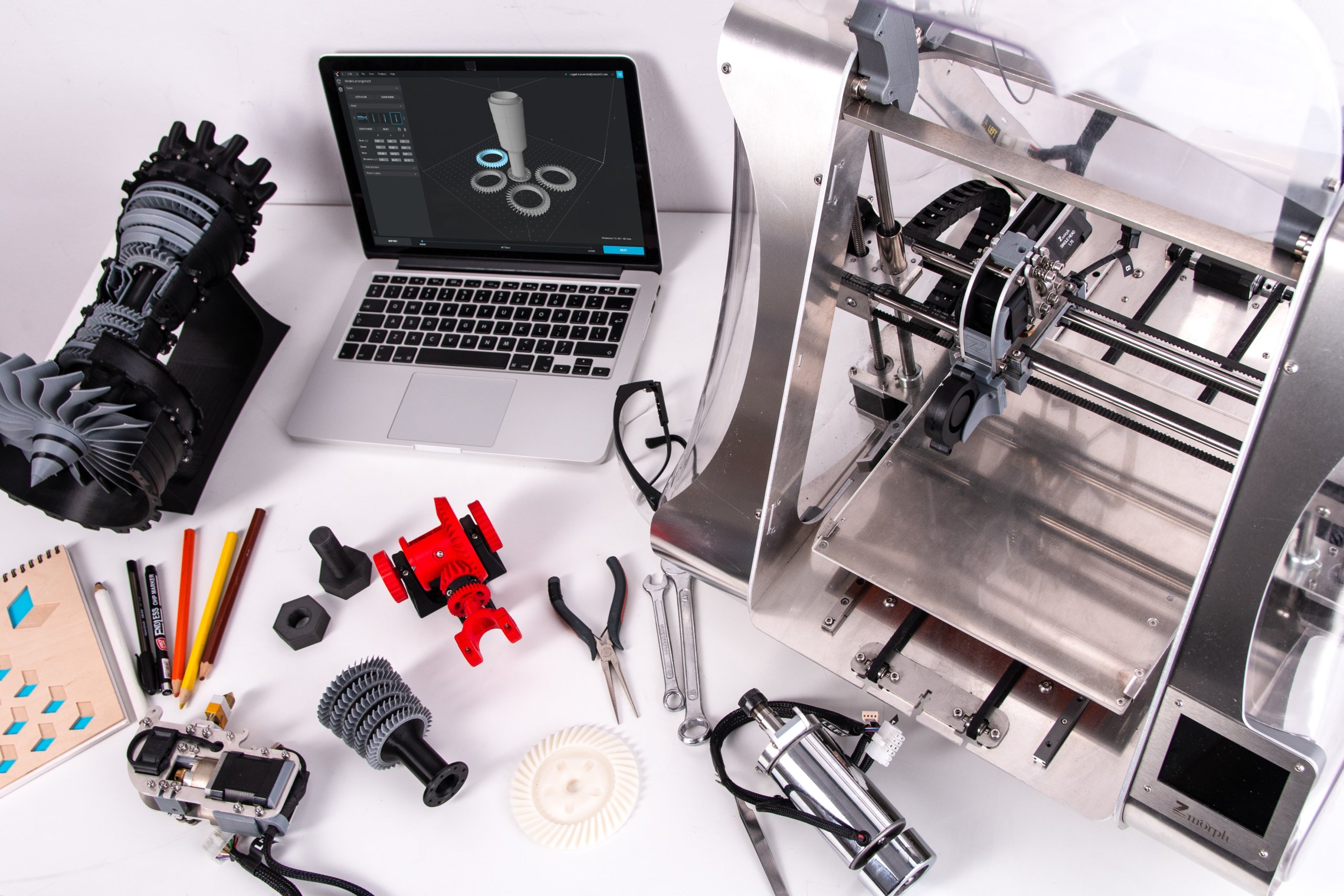

In our eager hunt for more sustainable ways to manufacture goods, 3D printing has become an increasingly promising option. There are various reasons for this: it is efficient, it is affordable and it can help reduce waste and lower CO2 emissions. The fact that it builds its items by adding materials, rather than subtracting them from large chunks of raw material, has a great potential for waste-saving - if done correctly. A European Commission study states that additive manufacturing (AM) could save up to 90% of the raw material needed for manufacturing by 2050. Similarly, the U.S. Department of Energy forecasts that AM might reduce waste and material costs by almost 90% and cut manufacturing energy use by 50%. Let us take a closer look at some of the ways in which 3D printing can help reduce the carbon footprint and make way for a sustainable production system:

AM as a Waste-Saver

A key environmental benefit of 3D printing lies in its ability to reduce waste thanks to the very essence of its manufacturing method. Unlike traditional, subtractive techniques that sculpt objects from raw materials - often resulting in more than 50% waste - 3D printing builds its objects layer by layer, using only the necessary material: a process that results in 70% to 90% less scrap waste.A Waste-Saving Design

3D printing uses advanced computer simulation, which allows for more precise designing and less resource-consuming prototyping than traditional manufacturing, such as CNC machining or injection molding. On top of this, 3D printing makes it possible to streamline and combine electrical and mechanical functionalities (also known as consolidation), so that fewer parts have to be designed and manufactured into the final assembly. This also simplifies the assembly process as fewer parts need to be welded or screwed together. Consolidation also makes objects more solid (they contain fewer seams) and carry less risk for leakage as it reduces vibrations. An example of consolidation technique is used in General Electrics’ Catalyst engine design, which originally required 855 engine components but has now been reduced to 12 titanium 3D-printed parts. This alteration has significantly reduced both the waste and the energy used in the production, rendering it more environmentally friendly.Repairing and Saving Outdated Equipment

Instead of throwing outdated production equipment on the scrap heap, manufacturers can use 3D printing to repair and replace specific parts. Through a method called laser metal deposition, it is also possible to repair worn-out metal parts that could not be fixed through welding or other traditional methods. Fixing instead of throwing is a key component of the battle against waste and has proven to be one of the areas in which 3D printing can play an important role.It Can Be Locally Produced

There is no need to ship parts, prototypes and products from far away when you have a 3D printer at your disposal. Not only does this lower the carbon footprint caused by planes, trains and trucks, but this quick and local manufacturing is also extremely useful in emergencies and crises. To take a recent example, the Covid-19 pandemic saw a huge rise in the use of 3D printing thanks to its ability to address supply-demand imbalances caused by traditional production and transportation. The agile and quick prototyping used in 3D printing rendered it an excellent first-responder to a global emergency, allowing for hospitals to manufacture everything from medical devices (e.g. ventilator valves, emergency respiration devices) and testing devices, to face masks and entire isolation wards locally.Fewer Parts, Tools and Warehouses

Additive manufacturing is a computer-to-part production process, which does not require molds, tooling or heavy labour between the design and production stage. Additionally - because you can print on demand - additive manufacturing does not require huge, energy-wasting warehouses for spare or overstock parts.Still a Long Way to Go

Despite its promising potential as a sustainable hero on the manufacturing scene, 3D printing - like all industries - has a long way to go before turning completely green. The biggest challenge today lies in what to do with the waste produced in the form of failed or obsolete prints, plastic powders, metal printing byproducts, support material and more. The relative cheapness of 3D printing is one of its greatest advantages, but it can also lead to an overproduction of prototypes and iterations, causing a lot of waste. That being said, our hope lies with the innovative culture that gave birth to 3D printing - in the many startups that are spending their days (and nights!) working to find new and greener ways to produce goods.Want to learn more about how 3D printing will change the way the world produces goods in the future?

December 7: AM Venture Day 2021, Copenhagen

Together with Danish AM Hub, Talent Garden has assembled 8 Nordic AM startups that are stretching the boundaries of 3D innovations while exploring new ways of using additive manufacturing for their business. They will all showcase why Additive Manufacturing should be a part of future manufacturing both for business- and sustainability reasons. Learn more and sign up by clicking here.

Article updated on: 09 August 2023

Don't Waste Your Talent. Turn It Into a Career With a Course That Fits Your Needs!

Talent Garden is your Digital Skills Academy, offering courses in Digital Marketing, UX Design, Digital HR and Data Analysis designed to launch your career.

Keep reading

3

min read

IdentiGeek: the 5 geeks who are changing the world

Happy Geek Pride Day! GEEK PRIDE DAY is celebrated on 25th May. So today it’s the world pride day for technology ...

Talent Garden

24/05/2019

4

min read

How to become a successful freelancer

How many people have or have been afraid of the word "freelancer"? Probably many. This is because sometimes we let ...

Talent Garden

04/03/2022

10

min read

How to create an effective and successful Project Management Plan

This article explains how to create a digital project management plan, starting from the traditional principles of the ...

Talent Garden

04/03/2022

9

min read

8 Best Project Management Software & Tools in 2020 for Effective Project Managers

Like every superhero, project managers need their own gadgets and tools. Thankfully, we have more at hand nowadays than ...

Talent Garden

08/09/2020